Dura-Blast 6 Cube Wheel Blast

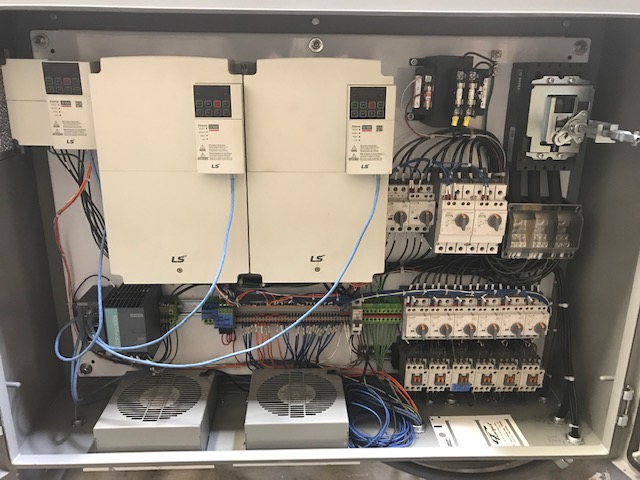

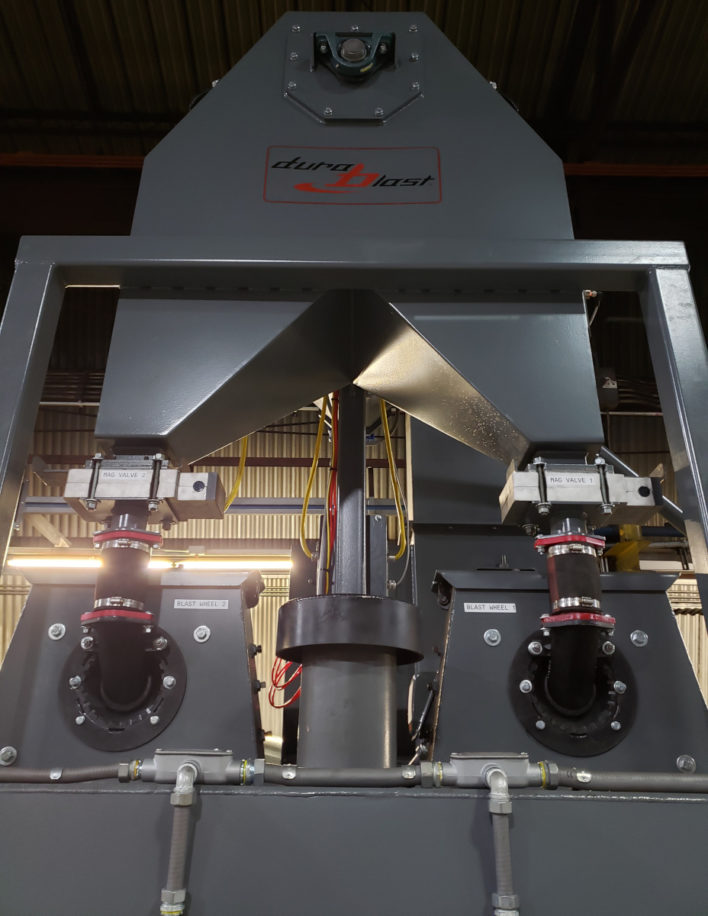

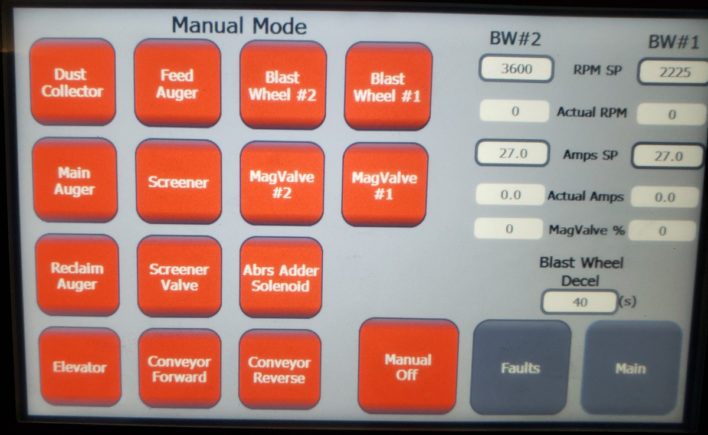

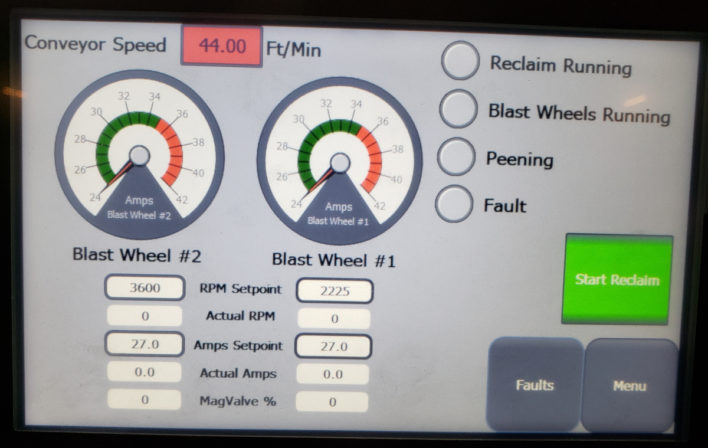

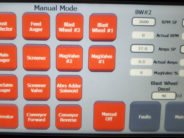

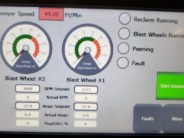

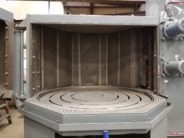

New Dura-Blast 6 Cube Wheel Blast, rubber belt tumble blast, shot blaster. PLC and touchscreen controlled, standard vertical lift door, optional mill safety, optional mounted dust collector, 15HP Goff style blast wheel assembly, and more.