New Machine: Dura-Blast Multi-Rebar Pass Through Blaster 2/4

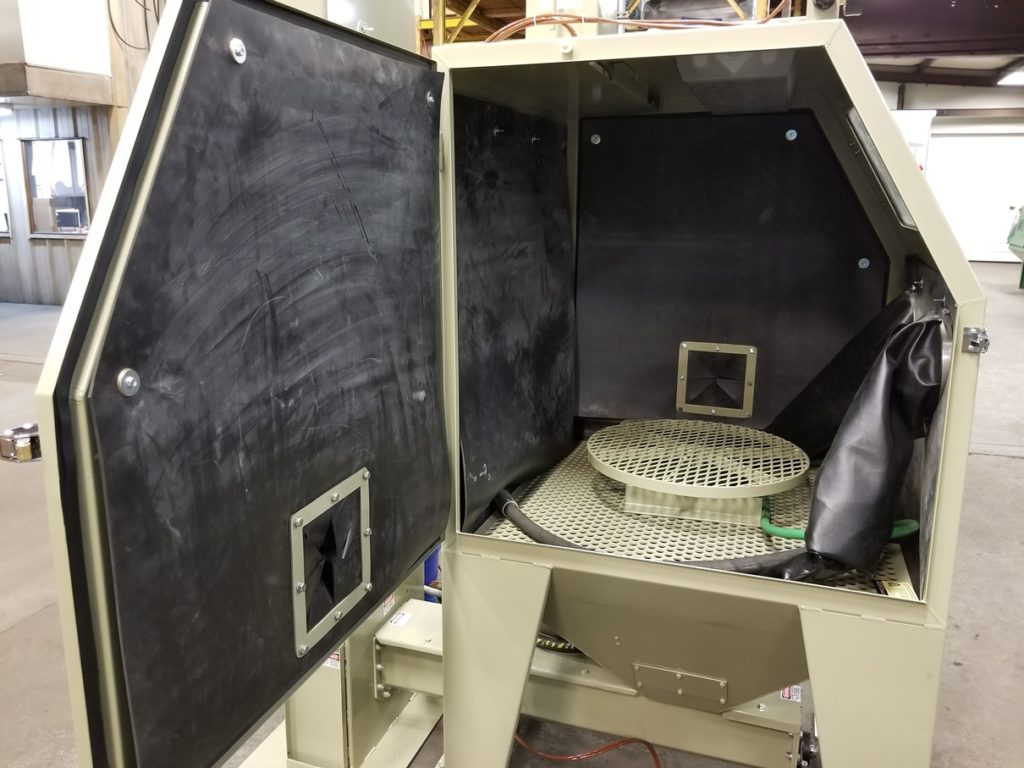

This is a new machine for Plan B, the Dura-Blast Multi-Rebar Pass Through Blaster 2/4. Our machine was custom designed and built to help get people into the rebar coating business with a minimal investment, while still providing a high speed, versatile cleaning machine. We use Goff style blast wheel assemblies, and the machine was made to ship with either one or two blast wheels. The machine can be built to ship with just one blast wheel, to keep the cost down, but that machine can be upgraded at a later time to a two-wheel machine. The one-wheel machine will run two bars at one time, while the two-wheel machine can run four bars simultaneously. We built this machine to run a range of bar sizes, from number 3 up to number 10 bar. On the smaller bar, we can achieve line speeds between 40’-50’ per minute. The Dura-Blast line of equipment is designed to last, and hold up under the harshest conditions. The cabinet is built from high quality abrasive resistant steel, and then lined with high chrome, white iron liners. We are partnered with a coating company that can provide the entire line needed for bar coating, or you can purchase our machine and dust collector for an existing line. The machine is easy to install, as it does not require a pit, and is a relatively short machine.