Wheelabrator WMT 84 Custom Rebuild

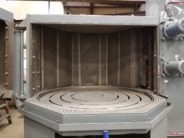

Plan B rebuilt this Wheelabrator 84” table blast machine for a local customer. Anyone familiar with these machines can probably pick out some of the things we added, but I’ll point them out for those unfamiliar with this style of Wheelabrator shot blast machine. The bucket elevator section had a lot of damage that had to be repaired, and we added a couple modern, air-operated abrasive valves for the blast wheels. The original machines just had slide gates that you had to manually open and shut to control the shot flow. As an extra safety, we added an air-operated door pin system, to help keep the door closed securely, even in the event of a power failure. We relined the main cabinet blast area with a combination of white iron cast liners and AR rubber wall liners. We typically replace and add extra liners and reinforcement to better protect the main abrasive blast areas. There were two variable frequency drives added for the two blast wheels, and there was a brand new, touchscreen and PLC controlled, electrical panel added to this machine. Plan B routinely takes older, worse-for-wear machines, and turns them into very functional, updated, and modern shot blast machines. We can rebuild them to a more “original” condition, or customize them to fit your specific application.

Posted in: Jobs