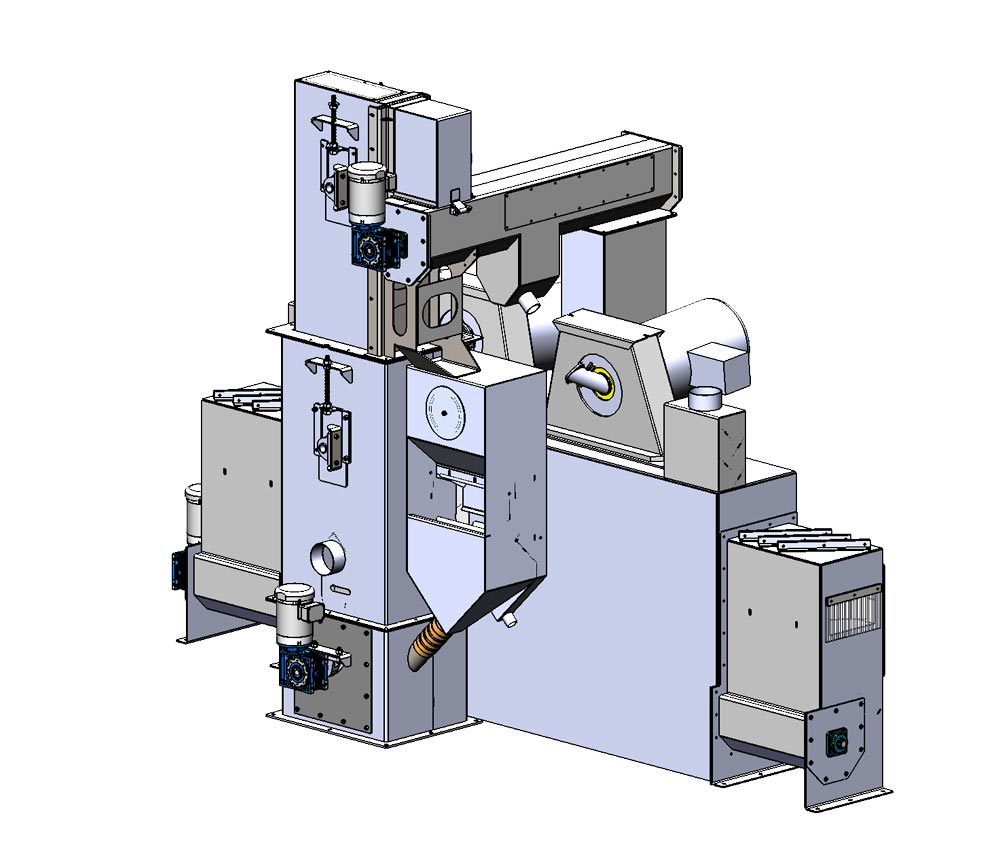

Plan B can source, rebuild, and fabricate rod, pipe, or bar (rebar) blast machines for a wide variety of applications. Skew roll blast machines are the most common type of bar blast machines, and can be built to accommodate multiple bars, and operate at various speeds. Larger 4-Wheel, “diamond” style machines are also used to blast even larger numbers of bars at one time, without the use of skew rolls. The skew roll versions can also be used to blast the outside diameter of sucker rod, pipe, or other cylindrical profiles without protrusions.

Rebar, or black bar, can be blasted to remove rust, mill scale, and corrosion, prior to being used in various structures, but is also blasted for cleanliness and profile prior to being coated. FBE, or fusion bonded epoxy (also known as fusion-bond epoxy powder coating) is a common coating for concrete reinforcing bars (rebar), steel pipe for pipeline construction, and piping connections or valves. The FBE coating helps protect various steel products from corrosion, which should result in longer life of the steel product, and lessen the chances of degradation in reinforced concrete structures. Abrasive blasting of steel pipe, rod, and bar, is still one of the most common ways to prepare a product prior to wet or dry coating. With the likelihood of additional federal money being allocated for “infrastructure” in the next several years, rebar blasting and coating should be a growing industry.

Call or email us if you’re looking for shot blasting equipment to get your coating business up and running.